Avina Factory

Welcome to Avina Fashion Jewellery, where every piece is crafted with precision, passion, and purpose. Our entire manufacturing process is handled in-house, allowing us to maintain tight control over quality, timelines, and confidentiality. From concept to completion you’re about to see how we bring your designs to life.

Sourcing Department

We have an extensive sourcing department that can source a wide range of raw materials, including gemstones of various types, pearls, cords, and so on.

Design Department

Jewelry is inspirational and based on creativity. Therefore you have the freedom to share your idea, photo, or sketch with us. As we have many years of experience and significant expertise in jewelry design, we can always work along your ideas and ensure that the goods are fit for bulk production.

Moulding Department

Once you have approved the 3D drawing, we will begin 3D printing and moulding. Our moulding masters have an average of 40 years of experience, and they will deliver the best results.

Models can be as straightforward as a simple ring or as intricate as elaborate jewelry with many interlocking colours and shapes.

The final mould is marvellous and resembles a rubber block with a negative impression of the jewelry. Our specialists artistically carve the mould to deliver the most intricate and unique designs.

Any piece of jewelry made by Avina is brought to life by an original metal model created based on labour-intensive hand-carved wax carving.

Wax casting techniques have been used for centuries to create sculptures and ornaments. However, we must emphasize that we will deliver your jewelry as miniature art sculptures so you can cherish them forever.

Waxing Department

Once the mother mould is finished, bulk production starts. At this point, we will provide you with samples to confirm before proceeding with bulk production. “bulk production” refers to the ability to obtain 100, 1000, or 10,000 units of the same product.

We shall treat each wax with care because it is the original shape of the final silver piece. Therefore, as long as the wax is in great condition, the silver component will appear perfect as well.

We shall treat each wax with care because it is the original shape of the final silver piece. Therefore, as long as the wax is in great condition, the silver component will appear perfect as well.

Casting Department

Casting Jewelry is the most common way for bulk production. The first step is to create a wax tree, and only after that the wax will be poured with a suitable scale of limestone and put into the oven for melting.

The silver will control the whole quality of the products. Control of the temperature degree and time is very important. Our silver moulding Master has many years of casting experience so you can expect spectacular results.

Refine Mould Department

The process of refining silver jewelry pieces taken from the silver tree is known as refining or polishing. It is a surface process that allows the jewelry to have a shiner appearance after refining. The refining process removes little unwanted pieces of the surface of the metal, leaving a flawless finish.

Each piece of your jewelry will be meticulously refined before being sent to other departments.

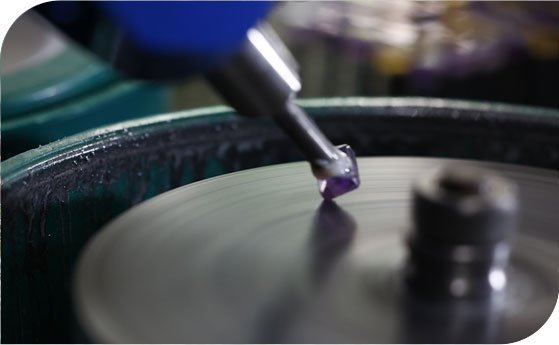

Stone Setting Department

This is the largest department because the majority of designs produced require gemstone settings, whether we talk about Cubic Zirconia crystal or natural gemstones. We have around 20 pieces of machinery and each of our employees is an experienced professional.

We are using the best and most well-known gemstone setting techniques like the followings: Claw/Prong Setting, Bezel/Rub-over Setting, Cluster Setting, Halo Setting, Channel Setting, Pavé Setting, Micro-pavé Setting, and so on. Furthermore, our setters understand the characteristics of each stone to maximize the brilliance of each gem.

Welding Department

Most jewelry needs welding, for example, necklace, bracelet, earrings, etc. Suitable welding controls the details of one piece of jewelry. A proficient welder manages the nuances of a single piece of jewelry.

Whether attaching two metal parts or securing some details, we will perform a quality check to ensure all welding is approved before proceeding to the following department.

Polishing Department

There are numerous methods for polishing. Some factories simply employ machine polishing, whereas Lurree personally polishes by hand each piece of jewelry. Our goal is to get the smoothest, shiniest, and most beautiful surface possible.

Engraving Department

Our workers use a machine to engrave each piece of your jewelry. To ensure brand consistency, we will create a mould for each engraving. Whatever the letter or pattern, we can engrave it for you. To ensure that the engraving is clean, we will plate it after finishing this process.

Handmade Department

This department’s primary responsibility is to ensure that most steps are done by hand, such as complete handmade jewelry design, gluing, braiding the cord, threading the beads, etc. If you have a handmade design or your design includes cords or beads, you have nothing to worry about since our specialists will create everything for you at the heist standards.

Not all gemstones are appropriate for the setting. For instance, pearl, opal, and turquoise could sometimes be glued to the metal to protect them. As a result, our department is also familiar with this technique.

Plating Process

We do not have a plating department, but we have a great relationship with the plating manufacturer and keep in touch with them at all times. We inspect each plating batch for quality to ensure it reaches our expectations.

QC Department

We have a dedicated Quality Control Department, and also several professional QC Departments that correspond to each department, such as raw materials, welding, stone setting, polishing, and so on. Once the quality is accepted, it can be sent on to the next department, thus we not only perform a final quality check but also ensure quality throughout each production phase. This ensures the quality of your jewelry while also giving you more control over the delivery schedule.

To ensure 100% quality approval, we will perform a QC check just before packing and another after packing to ensure that the package is also perfect. Quality is our way of life and “Doing Good” is always our goal.

Welcome to check our page How We Do Jewelry Quality Assurance for more details.

Packing Department

We will pack the goods according to your specifications and ensure that they are not easily broken during transportation. Our packing stage is always kept clean and organized, and we hope you are always pleased when you receive our product.

Stone Department

We have our gemstone division. Don’t worry if you can’t locate the gem you’re looking for on the market; we’ll find the perfect stunning gemstone to fit your needs.

Please kindly check our gemstone jewelry manufacturer page for more information.

Our People

As a 44 year old factory, our employees are always our wealth; no company can exist without its people. Therefore, we are constantly striving to be the most employee-friendly firm.

In addition to the salary, we provide boarding and housing. Our workplace is like a second home to our people, which is why many of our employees are long-term employees. Our employees grow within the factory, going through busy seasons together. Our busy season is in the year’s second half, but our team has demonstrated dedication and proficiency. We have been stronger than ever during times like the pandemic, and it all comes down to good management and treating our people like family. During this pandemic, we temporarily closed the factory to protect people, and some clients reduced or cancelled their orders. Fortunately, we got through all of this because of the consistent and high-quality product, observing a big increase in our client’s orders. So we’ve always kept our original vision to keep providing jobs for our people, and our people are always appreciative. We are incredibly grateful to them.

Each of your jewelry is made with labour and love by the people behind the machine.

Welcome to see our videos or contact us if you desire to know more about our factory.